PRODUCT

HOST PRODUCT

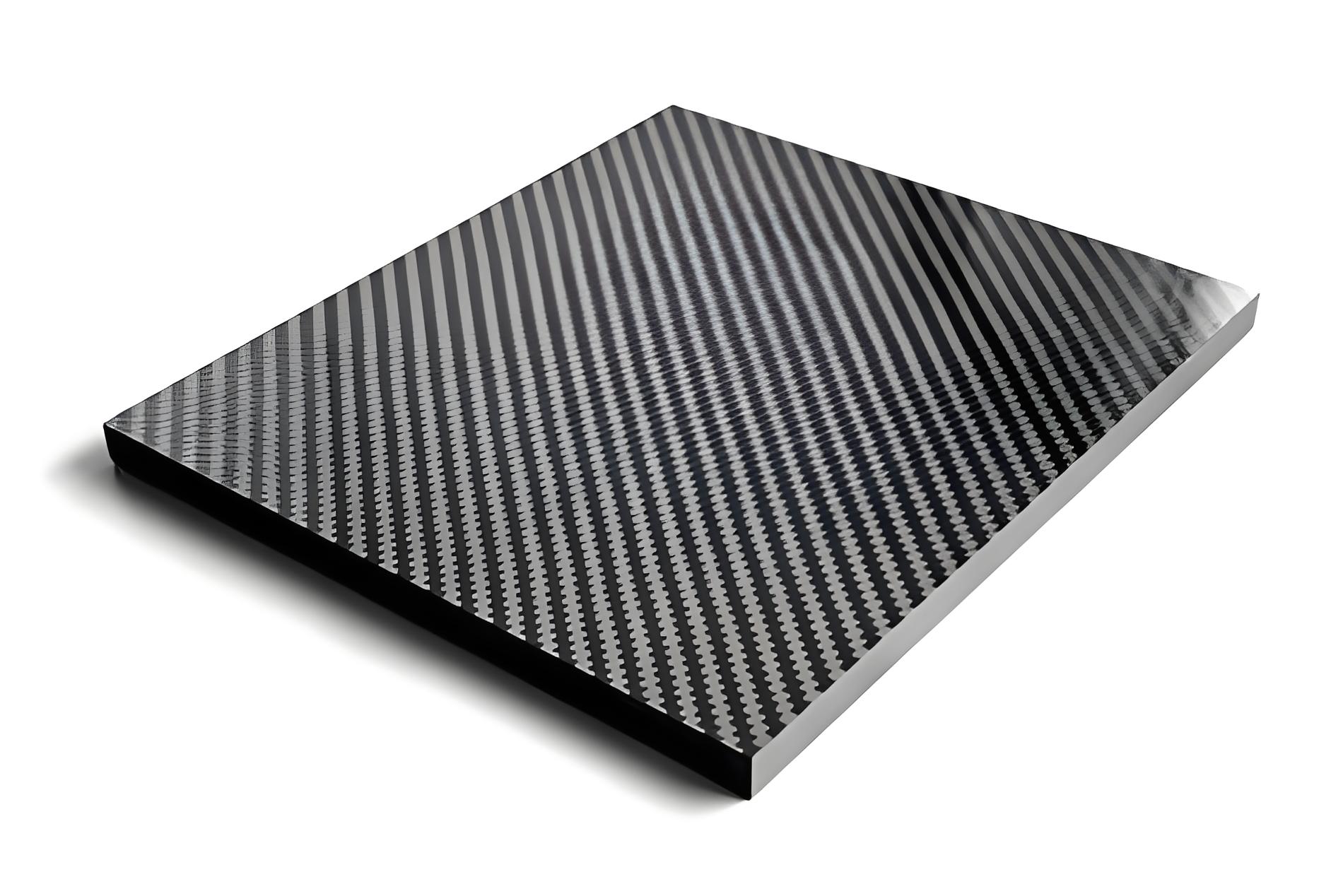

Comprehensive Analysis of Shengjie Carbon Fiber Plates

—Technical Specifications, Market Performance, and Product Portfolio

As a leading enterprise in China’s carbon fiber composite industry, Shengjie Composite Materials Co., Ltd. has developed a proprietary series of carbon fiber plates renowned for their exceptional performance and precise application adaptability. These products serve high-end sectors including aerospace, rail transportation, industrial equipment, and sports gear. Below is a detailed breakdown of technical test data, sales performance, and product models.

Core Test Data and Certifications

Shengjie carbon fiber plates strictly comply with international standards (ASTM D3039, ISO 527) and third-party certifications. Key performance metrics include:

| Test Parameter | Standard Value | Shengjie Test Data | Competitive Edge |

| Tensile Strength | ≥3,500 MPa | 3,800-4,200 MPa | 8%-15% above national standards |

| Tensile Modulus | ≥230 GPa | 240-260 GPa | High rigidity for load-bearing structures |

| Density | ≤1.6 g/cm³ | 1.55-1.58 g/cm³ | 50% lighter than aluminum |

| Interlaminar Shear Strength | ≥60 MPa | 65-70 MPa | Industry-leading delamination resistance |

| Coefficient of Thermal Expansion (CTE) | ≤0.5×10⁻⁶/℃ (axial) | 0.3×10⁻⁶/℃ | Superior dimensional stability in high-temperature environments |

Certifications:

Quality: ISO 9001, AS9100D (Aerospace), EN 45545-2 (Rail Fire Safety)

Environmental: RoHS, REACH, UL 94 V-0 (Flame Retardant)

Special Applications: DNV-GL Marine, CCS Marine Material Certification

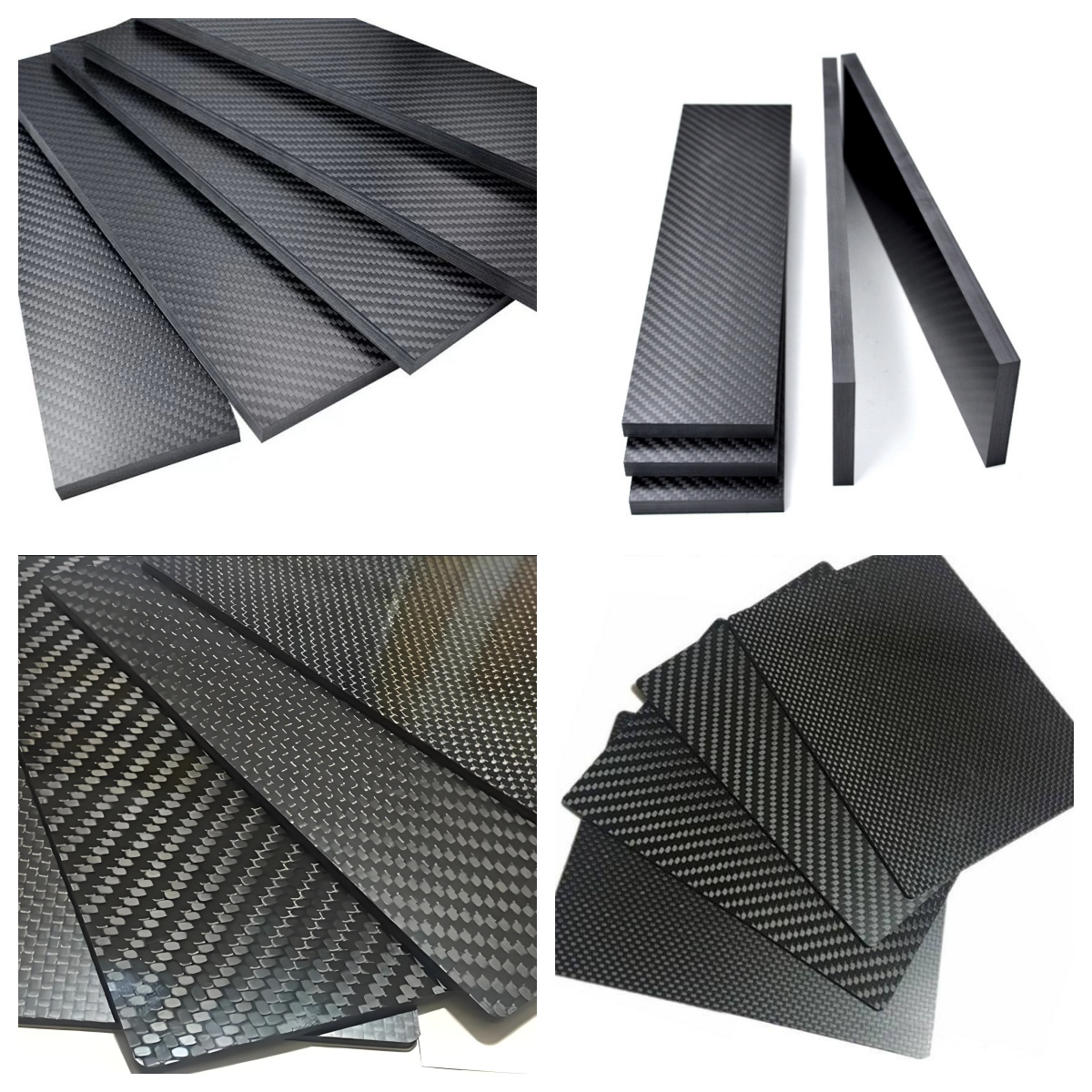

- Product Portfolio and Applications

Shengjie carbon fiber plates are categorized into five series based on fiber orientation, resin matrix, and functional properties:

- SJ-T300 Standard Industrial Plates

Specifications:

Thickness: 1.0-10.0 mm (customizable)

Fiber Orientation: Unidirectional (0°), Bidirectional (0°/90°)

Resin Matrix: Epoxy (standard)

Key Advantages: High cost-efficiency for robotic arms, industrial frames

Major Clients: ABB, FANUC (annual procurement >200 tons)

2、SJ-T700 High-Strength Lightweight Plates

Specifications:

Thickness: 0.5-5.0 mm (ultra-thin)

Fiber Orientation: Multi-axial (±45° woven reinforcement)

Resin Matrix: High-temp epoxy (180°C resistance)

Key Advantages: 40% higher impact resistance for drone fuselages, racing car chassis

Case Study: DJI Industrial Drone body lightweighting (35% weight reduction, 22% extended flight time)

3、SJ-T800 Aerospace-Grade Plates

Specifications:

Thickness: 0.3-3.0 mm (precision-molded)

Fiber Orientation: Quasi-isotropic (0°/±45°/90°)

Resin Matrix: Bismaleimide (BMI, 300°C resistance)

Key Advantages: NASA low outgassing compliance for satellite brackets, rocket fairings

Key Order: Structural components for CASC satellites (cumulative supply: 50 tons)

4、SJ-CF/PEEK Specialty Functional Plates

Specifications:

Thickness: 2.0-15.0 mm

Resin Matrix: Polyetheretherketone (PEEK)

Features: Wear resistance, self-lubrication, chemical corrosion resistance

Key Advantages: Replaces metal gears/bearings in semiconductor and medical equipment

Client Feedback: Vacuum chamber brackets for a wafer fab (3x lifespan, 90% lower contamination)

5、SJ-FRP Fire-Resistant Plates

Specifications:

Thickness: 1.5-8.0 mm

Flame Retardancy: UL 94 V-0, EN 45545-2 R1-HL3

Additional Features: Electromagnetic shielding (metallized surface)

Key Advantages: Integrated fireproofing and EMI shielding for high-speed train interiors, 5G 基站 enclosures

Project Win: Sidewall panels for CRRC EMUs (contract value >¥30 million)

III. Market Sales Data and Client Distribution

2023 Sales Overview

Total Sales: 2,800 tons (35% YoY growth)

Market Share: 22% of China’s high-end carbon fiber plate market (third-party data)

Regional Distribution:

Domestic: 65% (Yangtze River Delta, Pearl River Delta clusters)

International: 35% (Europe/USA: 18%, Southeast Asia: 12%, Middle East: 5%)

Key Client Cases

Automotive:

Tesla (Shanghai Gigafactory): SJ-T700 plates for Model Y battery trays (annual order: 150 tons)

BYD: SJ-FRP plates for electric bus roofs (GB/T 2408 fire safety compliance)

Energy: State Grid: SJ-CF/PEEK plates for ultra-high-voltage insulation (IEC 61462 arc resistance)

Sports: Decathlon: Custom SJ-T300 surfboard cores (retail sales >100,000 units/year)

R&D and Production Capacity

Production Facilities:

Fully automated prepreg lines (German Desma technology)

Large-scale autoclaves (Φ4.5m×12m, max pressure 10 bar)

Laser cutting precision: ±0.1 mm (aerospace-grade machining)

R&D Investment:

8.5% of revenue in 2023, 23 new patents (including 5 PCT)

Joint lab with Harbin Institute of Technology for lightweight materials

Services and Customization

Shengjie offers end-to-end “Material-Design-Manufacturing” solutions:

Rapid Response: Prototype technical proposals within 72 hours

Customization: Resin modification (toughening, conductivity), surface treatments (coating, plating)

Global Logistics: Self-operated bonded warehouses in Europe, USA, and Southeast Asia; JIT delivery

Shengjie Composite Materials Co., Ltd. – Redefining performance with data-driven innovation and delivering high-reliability carbon fiber plate solutions worldwide.

Note: Data sourced from 2023 internal reports and third-party testing. Contact Shengjie’s technical team for full test documentation.