PRODUCT

HOST PRODUCT

Shengjie Carbon Fiber Tubes: Lightweight Solutions for the Future

In the global industrial manufacturing landscape, where lightweighting and high-performance materials are paramount, Shengjie Advanced Composites Co., Ltd. has emerged as a leader in producing cutting-edge carbon fiber tubes. These tubes are widely adopted in aerospace, automotive, sports equipment, and high-end machinery. This article provides a data-driven overview of Shengjie’s carbon fiber tubes, supported by specifications, case studies, and real-world applications, ideal for international clients seeking reliable solutions.

1. Product Features & Technical Specifications

Key Performance Metrics

| Parameter | Shengjie Standard (SJ-CF-T300) | Aluminum 6061-T6 | Steel AISI 4130 |

|---|---|---|---|

| Density (g/cm³) | 1.55 | 2.70 | 7.85 |

| Tensile Strength (MPa) | 3,800 | 310 | 670 |

| Flexural Modulus (GPa) | 230 | 68.9 | 200 |

| CTE (10⁻⁶/°C) | 0.5 | 23.6 | 11.7 |

| Weight Saving Rate* | 70% vs Steel / 42% vs Aluminum | – | – |

*Calculated for equivalent strength requirements.

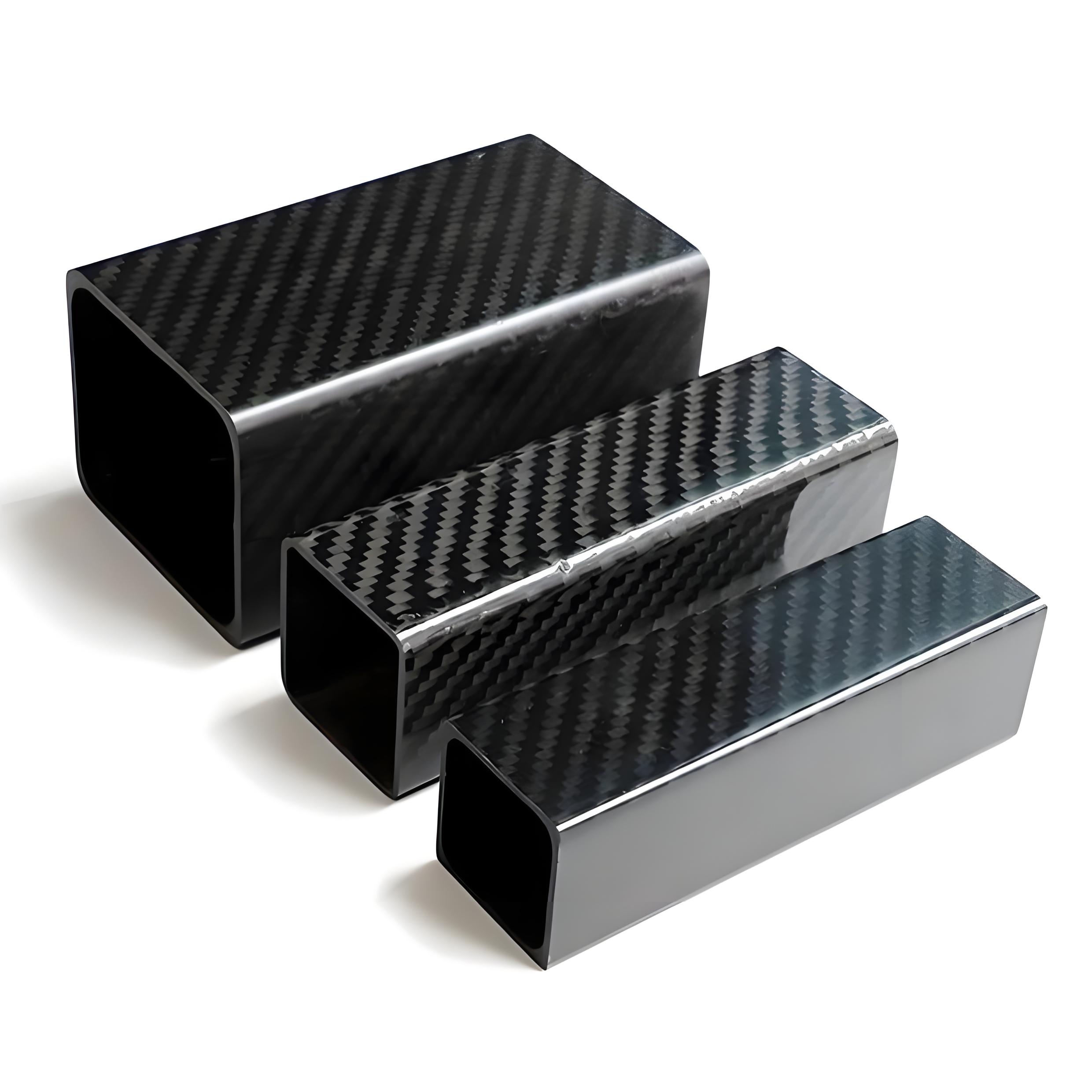

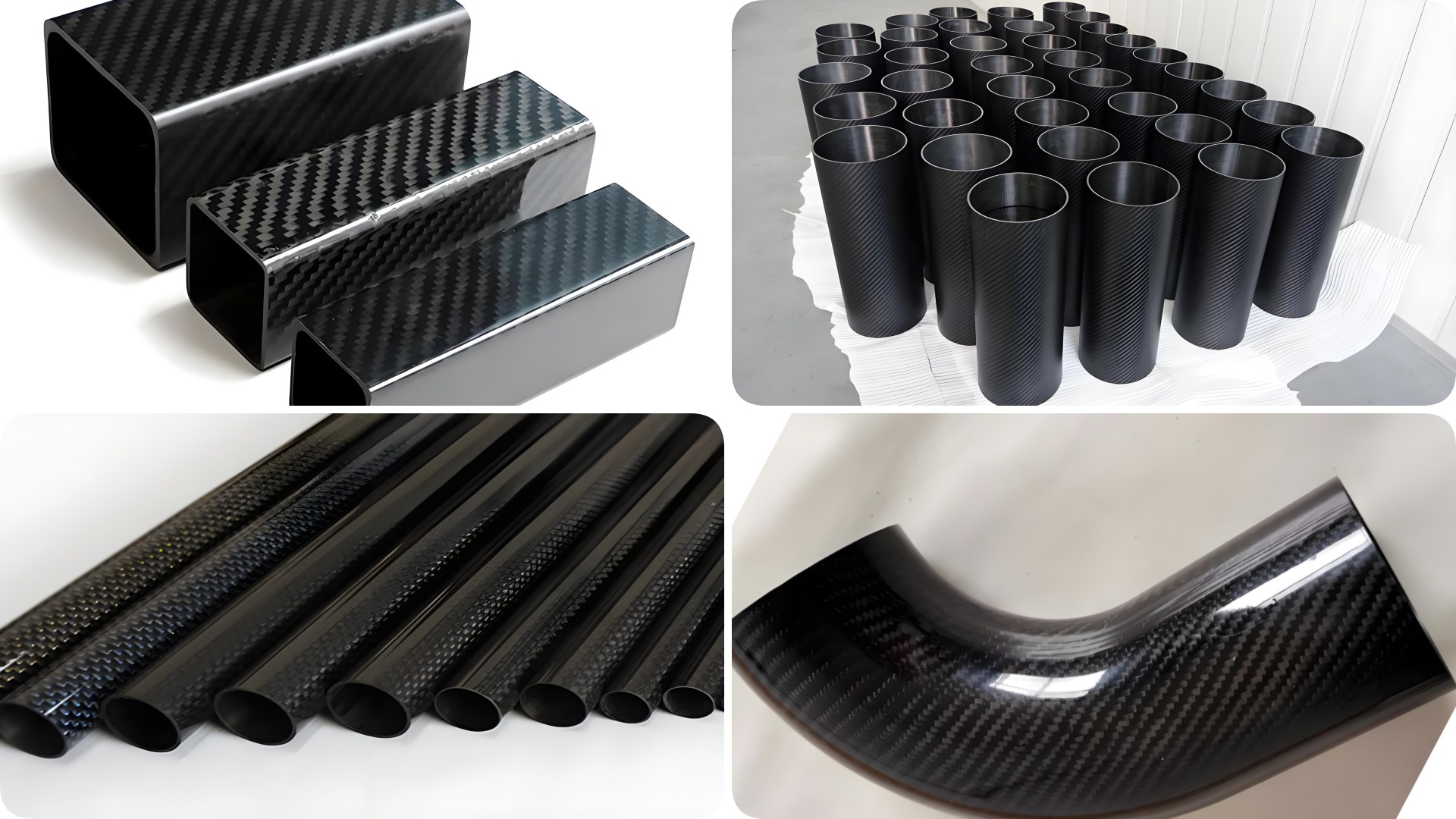

Product Range

- Standard Series: Diameter 6mm–200mm, wall thickness 0.5mm–10mm (drones, medical devices)

- High Modulus Series (SJ-CF-M60J): Tensile modulus ≥450GPa (satellite arms, robotic systems)

- High-Temperature Series (SJ-CF-HR): Continuous service at 400°C (engine components, industrial piping)

2. Manufacturing & Quality Assurance

- Materials: Toray T300/T800 (Japan) and SGL high-modulus fibers (Germany)

- Tolerances: Diameter ±0.05mm, straightness ≤0.1mm/m

- Certifications: ISO 9001, AS9100D (Aerospace), IATF 16949 (Automotive), with third-party fatigue testing (SGS verified, >10⁷ cycles)

3. Case Studies: Global Success Stories

German EV Battery Frame

- Challenge: Reduce weight without compromising crash resistance

- Solution: T800 carbon fiber tubes (50mm diameter, 3mm wall, 3K twill weave surface)

- Results:

- 55% weight reduction vs aluminum → 8% longer vehicle range

- Passed ECE R100 crash tests

- 12% lower production costs at scale

Australian Solar-Powered Drone

- Requirement: Ultra-light wing spar (<1.2kg/m) stable across -40°C to 80°C

- Shengjie’s Fix: M60J high-modulus tubes with square profile (25mm×15mm)

- Outcome:

- 200% higher strength-to-weight ratio vs aluminum

- Passed 10,000-hour salt spray test

- 30% faster time-to-market (pre-drilled/coated in-house)

U.S. Robotic Arm

- Issue: Steel arms caused inertia-driven positioning errors

- Collaboration: Carbon fiber-titanium hybrid tubes reduced weight by 62%

- Impact:

- Positioning accuracy improved to ±0.01mm

- Annual maintenance savings: $250,000 (corrosion resistance minimized downtime)

4. Service Advantages: End-to-End Support

- Rapid Prototyping: 7-day lead time for samples (3D files or physical measurements accepted)

- Cost Efficiency: Bulk pricing from $35/m (varies by specifications)

- Global Delivery: 15-day shipping to EU/NA regions, DDP terms available

5. Why Choose Shengjie?

- Proven Track Record: 1,200+ tons exported globally, 92% customer reorder rate

- Hybrid Customization: Kevlar, fiberglass, or metal-composite integration

- Sustainability: 85% carbon fiber scrap recycled; REACH and RoHS compliant

Appendix: Product Selection Guide

| Application | Recommended Model | Typical Specs | Cost Range ($/m) |

|---|---|---|---|

| Drones/Electronics | SJ-CF-T300 | Φ10mm×1mm wall | 28–35 |

| Racing Roll Cages | SJ-CF-T800 | Φ75mm×5mm, ±45° layup | 120–150 |

| Marine Masts | SJ-CF-HR | Φ150mm×8mm, seawater-proof | 200–240 |