PRODUCT

HOST PRODUCT

| TECHNICAL DATA SHEET | ||||

| Manufacturing Method : | Round Carbon Fiber Tube – By Roll Wrapping Process | |||

| Custom Shape Carbon Fiber Tube – By Compression Moulding Process | ||||

| Structure | UW | U= Undirectional Prepreg | W= Woven Prepreg | |

| Raw Materials : | Carbon Fiber , Epoxy | |||

| Diameter Range O.D. | From 6mm O.D. to 300 mm | |||

| Wall Thickness | From 0.5mm to 20mm | |||

| Length : | From 0.05 Meter to 3.5 Meters | |||

| Colors : | Black Or Any Color from RAL ; | |||

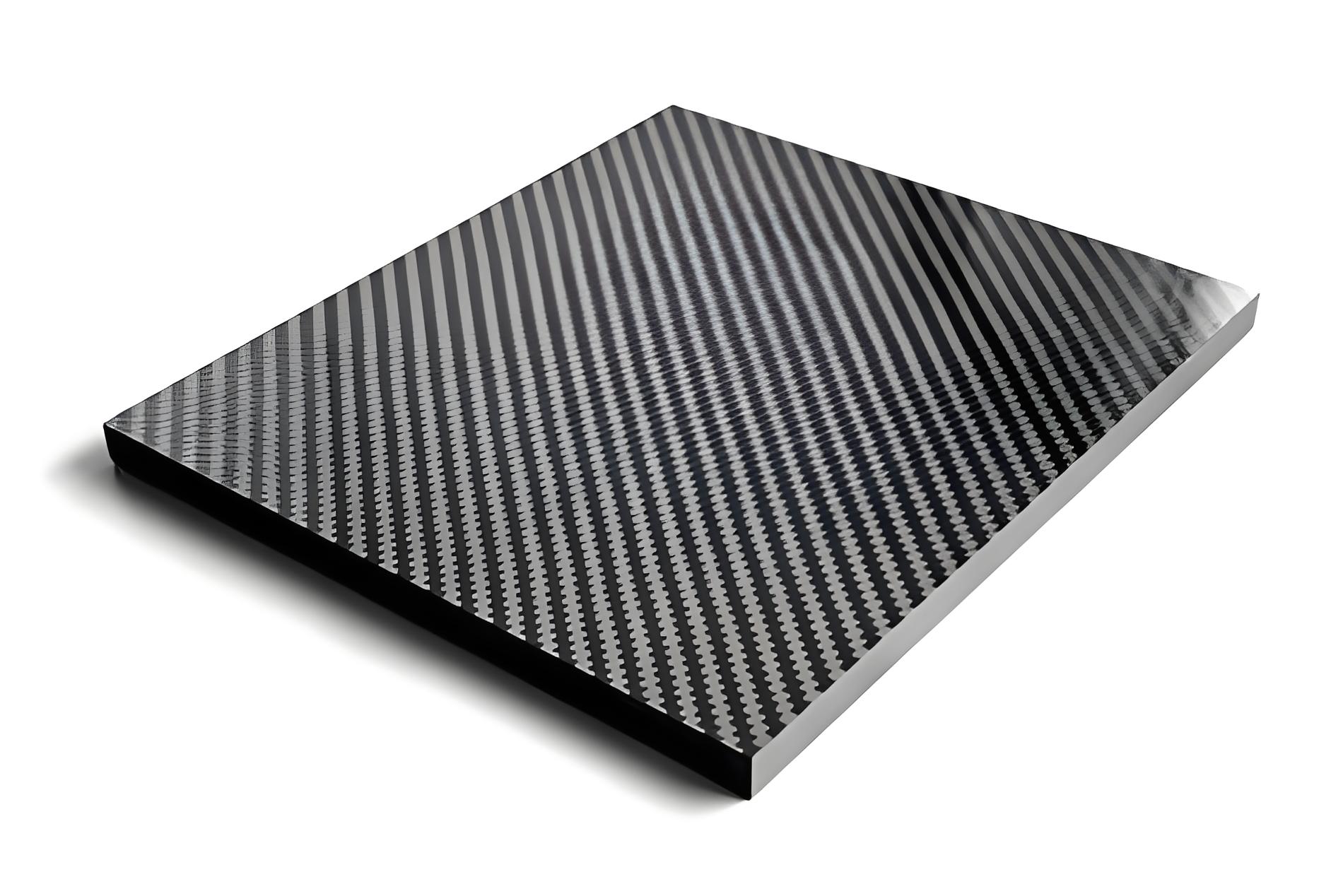

| Surface Treament : | Matt Finish & Glossy | |||

| Water Absorption | < 1,5 w-% | |||

| Denisty | 1.5g/cm3 | |||

| FIBER TYPE | HS Carbon | HM Carbon | ||

| Stifiness | 90- 100 Gpa | 120-180 | ||

| Bending Strength | >600 Mpa | >500 Mpa | ||

| Tensile Strength | > 650 Mpa | >550 Mpa | ||

| Denisity | > 1.5g/cm3 | >1.5g/cm3 | ||

Features and use:

Carbon Fiber Exhaust Pipe has the advantages of high strength, long service life, corrosion resistance and light weight. It is widely used in kites, aviation model aircraft, various supports, equipment spindles, automation equipment, etching machines, medical stretchers, sports equipment and other products. A series of excellent properties, such as dimensional stability, conductivity, thermal conductivity, small coefficient of thermal expansion, self-lubrication, energy absorption and seismic resistance. It has the characteristics of high specific modulus, fatigue resistance, creep resistance, high temperature resistance and wear resistance.