PRODUCT

HOST PRODUCT

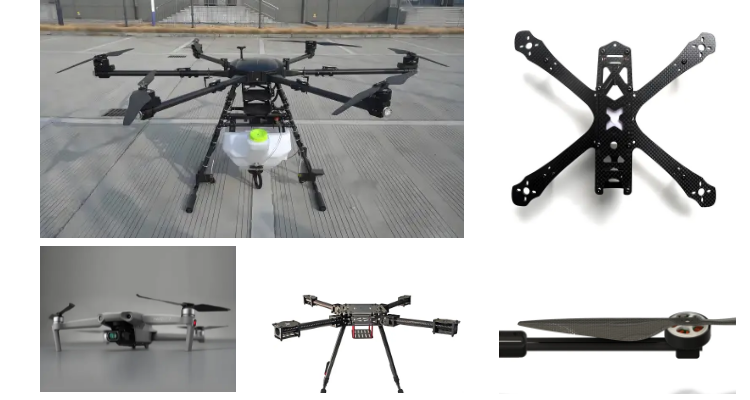

Shandong Shengjie: A Pioneer in Intelligent Manufacturing of Carbon Fiber Drone Components

Amid the rapid development of the drone industry, carbon fiber composites have become the preferred material for high-end drone structural components due to their lightweight, high strength, and corrosion resistance. As a leading enterprise in China’s precision carbon fiber manufacturing sector, Shandong Shengjie leverages its profound technical expertise, advanced manufacturing capabilities, and extensive industry experience to continuously provide high-precision, high-performance carbon fiber component solutions for the global drone supply chain, establishing itself as a core driver of high-quality industry development.

1. Full-Chain Production Capabilities: Precision Manufacturing from Material to Finished Product

Shandong Shengjie has established comprehensive production capabilities spanning the entire lifecycle of carbon fiber drone components, forming a closed-loop process from raw material selection, structural design, process development, to mass production. The company is equipped with high-end facilities such as automated prepreg cutting systems, autoclave molding equipment, and five-axis CNC machining centers, enabling millimeter-level precision in processing complex curved parts. For critical components like drone propellers, fuselage frames, landing gear, and gimbal brackets, the company’s annual production capacity exceeds 30,000 units, with a product yield rate consistently above 99%, meeting the stringent reliability requirements of military-grade drones.

In terms of process innovation, Shandong Shengjie has independently developed multi-directional fiber layup optimization technology. By utilizing intelligent simulation systems to precisely control the angle and density of carbon fiber fabric layers, the company achieves a 30% weight reduction for components while increasing tensile strength to five times that of traditional metal parts. Additionally, through flexible configuration of modular production lines, the company rapidly responds to customized client demands, seamlessly transitioning from prototype validation to large-scale delivery, with lead times compressed to as short as 10 days, empowering drone manufacturers to seize market opportunities.

2. A Decade of Expertise: Deep Industry Experience

Since entering the carbon fiber manufacturing field, Shandong Shengjie has focused on technological breakthroughs in the drone sector, accumulating partnerships with over 300 global drone enterprises. Its solutions span applications such as agricultural crop protection, power line inspection, emergency rescue, and military reconnaissance. The company has actively participated in multiple national-level drone R&D projects, with its carbon fiber/titanium alloy composite structural components successfully applied to a long-endurance reconnaissance drone model, achieving a breakthrough of 48 hours of continuous flight without structural fatigue.

In collaboration with institutions like Harbin Institute of Technology and Beihang University, Shandong Shengjie has established joint laboratories to advance research on carbon fiber-resin interface optimization and integrated molding processes. The company holds multiple national patents and pioneered the “gradient temperature curing process,” which resolves deformation challenges in high-temperature molding of large-scale drone wing beams, reducing flatness errors to below 0.05mm—a globally leading standard.

3. Core Strengths: Technology-Driven Quality Assurance

1. Material Science Innovation

Shandong Shengjie collaborates with top carbon fiber suppliers such as Toray and Zhongfu Shenying to tailor material solutions for diverse environments: high-modulus T800-grade carbon fiber for plateau low-temperature conditions, corrosion-resistant epoxy resin systems for marine salt-spray environments, and polyimide matrix materials for high-temperature regions, ensuring component stability under extreme conditions.

2. Digital Manufacturing System

By implementing an MES intelligent manufacturing management system, the company achieves end-to-end digital control from order scheduling to quality traceability. Each production line is equipped with in-line 3D scanners to monitor deviations between machined parts and design models in real time, coupled with adaptive compensation algorithms to maintain dimensional tolerances within ±0.02mm—exceeding ISO 2768 precision standards.

3. Rigorous Quality Control

The company partners with aviation-grade testing centers equipped with industrial CT scanners and ultrasonic flaw detectors to conduct over 20 performance tests on each batch, including porosity, interlaminar shear strength, and fatigue life. Its drone rotors withstand 2 million cycles of load testing—1.5 times the industry average—earning long-term partnerships with leading brands like DJI and XAG.

4. Service Empowerment: Building a Client-Centric Ecosystem

Shandong Shengjie prioritizes client needs by offering integrated “design-manufacture-test” services. Its engineering team completes Design for Manufacturability (DFM) analysis within 48 hours, proposing structural optimizations for weight reduction and cost efficiency. Post-sale, the company maintains a nationwide service network with a 72-hour emergency response commitment, providing component replacement and damage repair services to minimize client downtime.

Conclusion: Leading the Lightweight Future

From material innovation to intelligent manufacturing, Shandong Shengjie drives the lightweight revolution in the drone industry through carbon fiber technology. Moving forward, the company will increase investments in 3D woven composites and intelligent non-destructive testing, striving to become a global “hidden champion” in drone components and deliver more efficient, reliable carbon fiber solutions to the world.